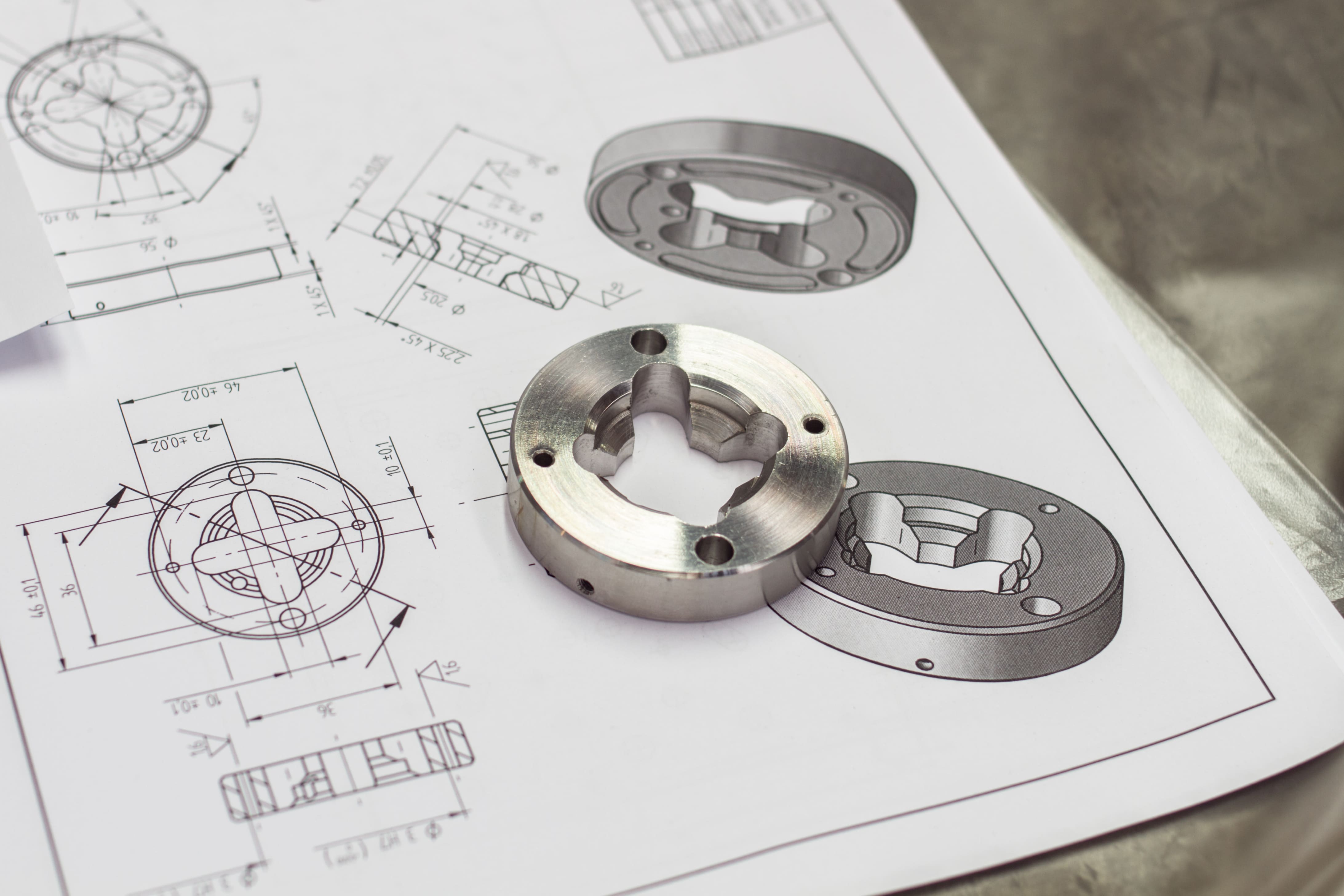

The die casting industry is evolving. Today, we know much more details about the features of different alloys and can achieve more impressive results in terms of quality and production speed than a couple of decades ago. That also means that the design phase of any die casting project is now more complex than ever before. In one of our previous blogs, we talked about some of the key design decisions you need to focus on. Today, we’re diving deeper into what you should consider once your parts are solidified and ejected from molds.

Die casting is the most widely spread method of producing metal parts. It offers numerous advantages, such as enabling high-speed and high-volume production, giving the ability to create complex designs with precision, reducing material waste, etc. However, before launching your die-casting project, you need to know the difference between various types of die casting and other production methods. In one of our previous blogs, we compared die casting and 3D printing, and today, we’re looking at Pressure and Gravity Die Casting.

Jul 6, 2021 9:17:00 AM

Read More »

What do toy cars, cookware, and streetlights have in common? Apart from the fact that everything in this list can be red, yellow, and green, all these objects can be die-cast. Although die casting appeared in 1838 for the printing industry and is now famous as a method of producing metal parts for manufacturing, you use die castings every day without even realizing it. In this blog, let’s shed some light on where you see, touch, and work with die-cast products.

Jun 3, 2021 12:12:18 PM

Read More »

Do you know the most successful Rolls-Royce ad of all time? “At 60 miles an hour, the loudest noise in the new Rolls-Royce comes from the electric clock.” Although it’s not said directly, it’s clear that everything in that car works so quietly and smoothly that you don’t even notice it. At Simalex, we believe that all equipment should work the same way: precisely, like clockwork, although making a lot of noise. Here’s a sneak peek into the equipment we use, how we maintain it, and why it matters to you, the customer.

Apr 27, 2021 11:37:00 AM

Read More »

New solutions appear in different sectors every day. One of them is 3D printing for the manufacturing industry. Today, we’d like to compare die casting, which we already described in one of our previous blogs, to a cutting-edge solution, 3D printing, also known as additive manufacturing. What are the benefits of each manufacturing method? What are the differences? How to choose the best solution for your project? We’re answering these questions in this blog.

Apr 6, 2021 9:17:00 AM

Read More »

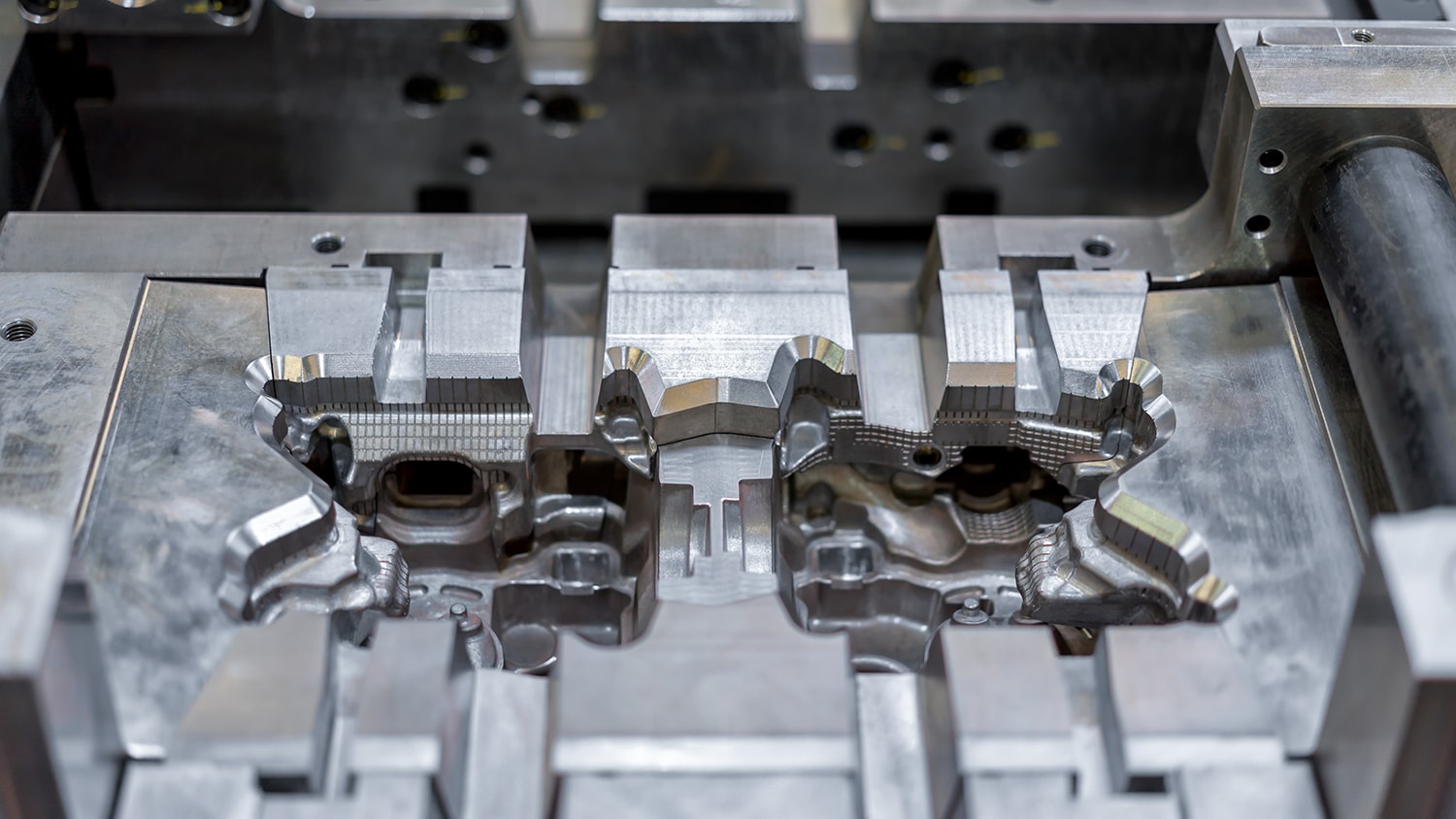

What’s the use of a house that was custom-built for you, but you can’t get inside because no one gave you the keys? The same is true for die casting because it is more than just pressing liquid metal into a mould under high pressure. This process includes several stages, from design to actual use. That’s why it’s crucial to know what will happen after your part is cast and what options you have as a customer. Today, we’re looking into several finishing options.

Mar 4, 2021 11:34:00 AM

Read More »

One of the many benefits of die casting is the longevity of its metal alloys. These commonly used alloys for die casts are strong and bear long service lives.

Oct 29, 2020 12:05:53 PM

Read More »

By offering endless possibilities for components and shapes in an efficient process, die casting is a clear winner among manufacturing techniques. But what about its cost efficiency?

Aug 28, 2020 10:40:46 AM

Read More »

Besides its economic benefits, time efficiency, and general reliability, there is another excellent argument to opt for die casting over other metal casting methods: the comparatively low environmental impact.

Jun 19, 2020 8:20:55 AM

Read More »

At Simalex, we produce a variety of parts and essential components for different industries, and we pride ourselves in the versatility and accuracy of our parts. Recently, our production has seen a significant change due to the rising demand in medical ventilators for CoVid-19 patients in intensive care. Keep reading to see how we're adapting to help during this time of crisis.

Apr 21, 2020 11:44:19 AM

Read More »